Successful Startup of Laser Processing Machine in Eschbach

Dear colleagues,

Today, we would like to report on a success story from the Value Stream Industrial & Engineered Systems (IES), which is also a milestone in the area of laser materials processing (LMP) for PI.

The subsegment 'Laser Materials Processing' is part of the PI segment 'Industrial Automation'. Previously, this subsegment concentrated on manufacturing and delivering components consisting of positioners, control and software, with the focus on the area of LMP, with restricted testing for their suitability for PI’s targeted applications.

In April 2022, the Value Stream IES could commission construction of an inhouse LMP machine for better understanding of the different processes that occur in Laser Material Processing such as marking, engraving, drilling and welding. This now enables PI to test components in the application flexibly, independently and in a customer-oriented way, therefore understanding customers' requirements better, and generating a deeper depth of expertise.

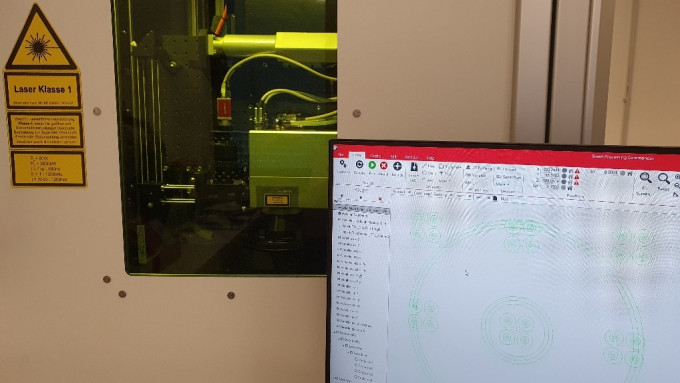

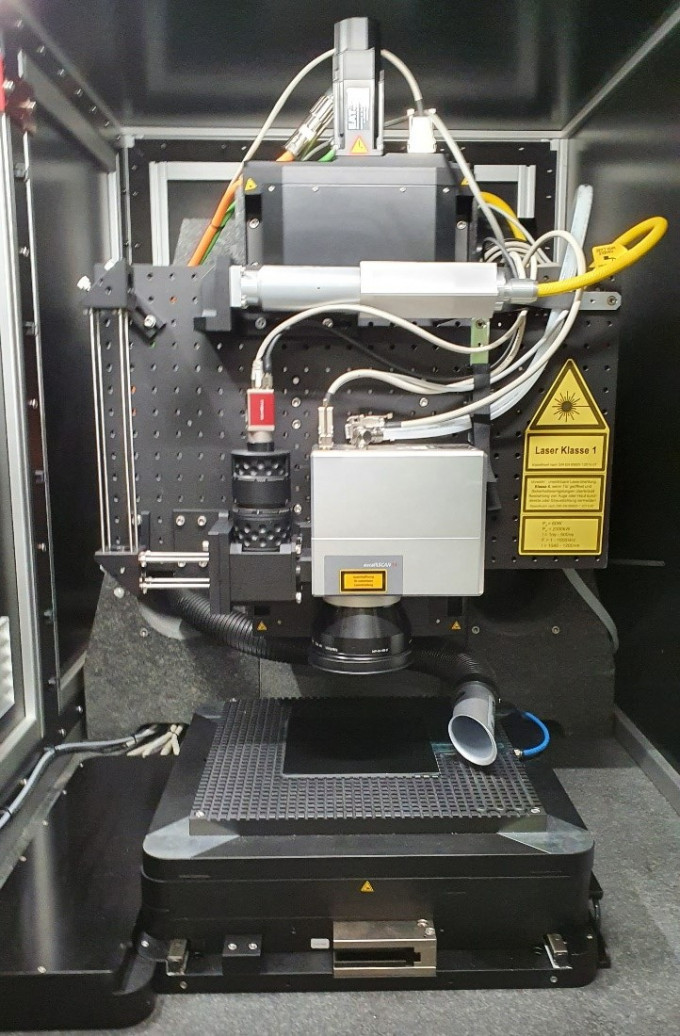

The complete LMP machine consists of an infrared laser source, a galvo scanner from Scanlab, a workpiece vacuum chuck, a XYandZ stage system from the Value Stream Motorized Positioners, safety technology including the necessary laser protection machine casing, and an industrial camera. The machine is controlled by ACS electronics and the ACS Smart Processing Commander (SPC) as CAD / CAM software.

In constructing such a machine inhouse, our application and systems engineers have significantly increased both their practical and theoretical understanding of the required mechanical and system interfacing required between components used in a laser machine and the usage of ACS’s SPC software.

Those involved are now providing highly valuable insight and feedback of how PI's products and solutions roadmap should evolve in terms of better mechanical interfacing, control systems, and software, to support laser machine builders and integrators. An example of this will be the upcoming configurable multi-axes platforms for laser material processing.

We are ready to partner with new customers by offering motion centric products and solutions that are not designed in isolation from their actual usage. This inhouse machine will not be an offering made to our customers.

We would like to say a big thank to all of the participants who contributed towards this milestone.

If you have any questions, please contact either of us below.

Best regards

Dr. Markus Blust

Head of Value Stream Industrial & Engineered Systems – DPG

Dr. Cliff Jolliffe

Head of Segment Marketing– Industrial Automation