PI Ceramic Expands the Application Range of Piezoelectric Ceramics

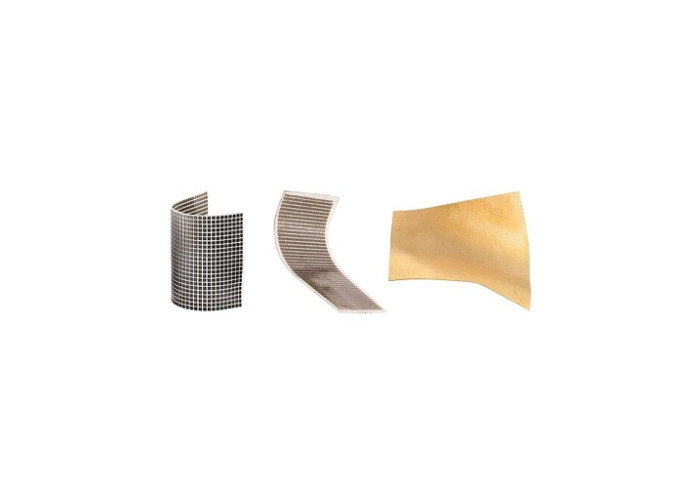

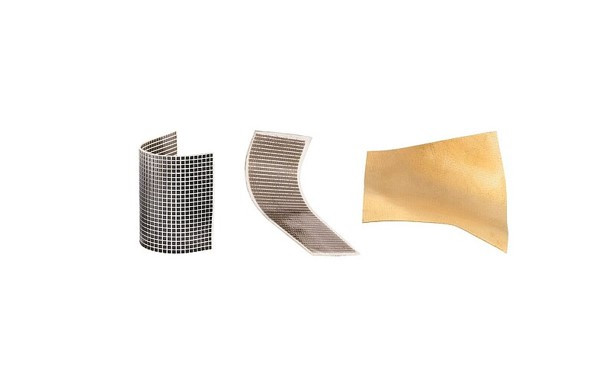

PI Ceramic introduces the new product category “Piezoceramic Composites” based on the development of a new manufacturing technology in which piezoelectric ceramics are embedded in filling polymers. Both materials with high stiffness and highly elastic polymer matrices are used as filling polymers. The basic functionalities of piezoceramics, namely ultrasonic conversion and actuator technology, can thus be combined with the properties of the filling polymers.

In addition to excellent adaptability to different shapes, the polymer content offers many other advantages over all-ceramics. For example, composites can easily adapt to environments with different acoustic impedances. The term refers to the resistance to the propagation of (acoustic) vibrations in a medium or at the transition between propagating media. This allows for a wide range of applications. In medical technology, high-intensity focused ultrasound (HIFU) applications or diagnostic imaging benefit from this. Industrial applications also take advantage of these properties. Examples include flow rate metering or non-destructive testing.

Different Filling Polymers

To enable the best possible adaptation to the respective application, PI Ceramic offers two different types of filling polymers for prototype development: Epoxy resins are used for rigid composites, while softer, silicone-free polymers are available for highly flexible composite structures.

Contact person: Dr. Patrick Pertsch, CEO PI Ceramic