Software Paves the Way for Future Orders

Dear Colleagues,

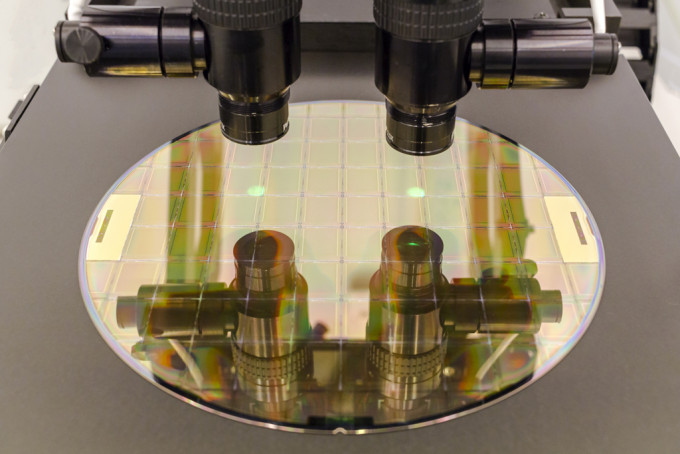

Software development, as well as its integration into customers’ development and working environments is extremely important in making customer applications more effective and efficient. The feedback from one of our biggest customers in the area of semiconductor manufacturing / wafer inspection clearly shows this.

Within the realm of a project that took two weeks to develop, Theo Fischer, Development Engineer for Software Development, developed an individual interface in LabView. Using this, customers can automatically correct the different changes in length of the struts whilst relaxing a NEXLINE® hexapod. This enables the closed loop target position to be held extremely accurately, even in a stress-free state, and the further reduction of noise. The user interface allows the deviation of the target position from visual and strut-dependent tolerances to be specified.

The challenge lies in combining piezo-specific expertise with the programming of a suitable procedure, so that this can be integrated into the customer's existing LabView controls.

In particular, we would like to thank Christopher Mock, Senior Principal Piezo Basis Technology, who supported Software Development with the necessary piezo drive expertise. Communication with the controller takes place using the LabView driver, which is delivered as a standard with our software, and translates the data in LabView into GCS commands. This is already the second successful project of this kind since 2020, and our customer is very satisfied.

These projects improve the use of our products by the customer, and really can pave the way for future orders. With this customer, we are currently discussing around ten similar enquiries on this kind of mechanics.

The customer uses the hexapods to adjust a mirror in a new EUV Reticle Inspection Machine. As this requires a high level of stability, a NEXLINE® drive is used.

The project was a challenge internally as, whilst developing the customer application, we identified a bug in the controller's firmware, and could therefore contribute towards improving the product.

By offering this kind of 'paid services', Software Development would like to make their know-how in software development and integration available to the customer, and has already provided dedicated staff for this purpose.

The products PI used for this are:

- P-911K NEXLINE® hexapod

- E-712K controller

- PI software suite, including the LabView driver

For further questions on the actual setup from the offer, or any general questions on our software, please directly contact Alexander Frings, Product Marketing Manager or Axel Reschke, Head of Software Development.

Best regards

| James Berge | Dr. Christian Enkrich |

| Director Product Marketing - Global | Director Platform Development - Global |