Lean Management Project “Leica Line” Completed Successfully

For more than ten years, PI has been mounting the drive platform for the so-called total stations of its customer Leica Geosystems. These are complex measuring devices that are used for real estate surveying and for the creation of large-scale plans and maps.

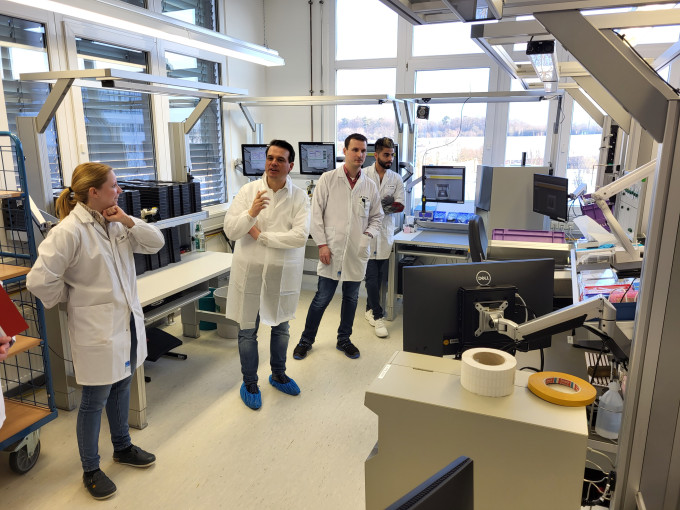

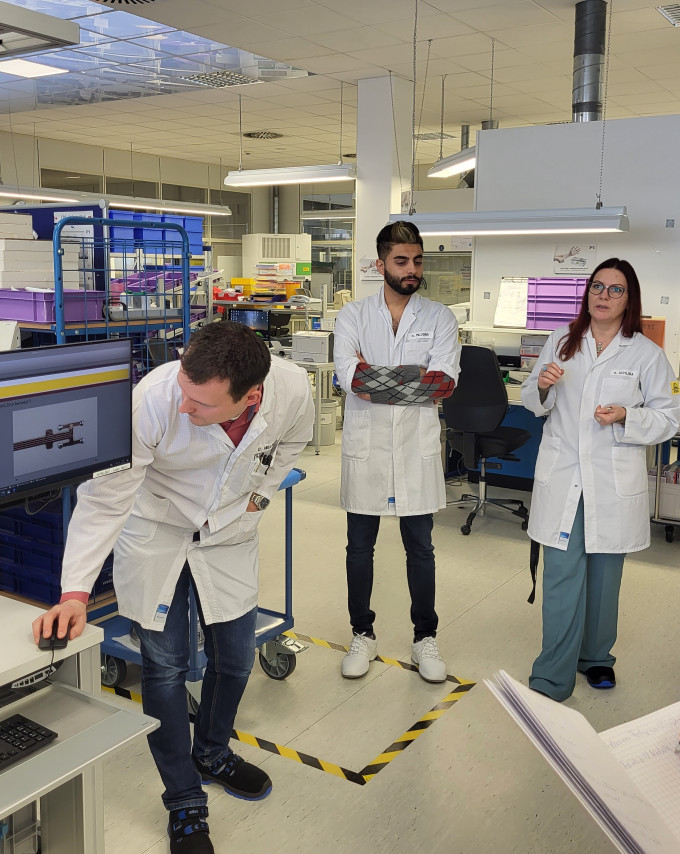

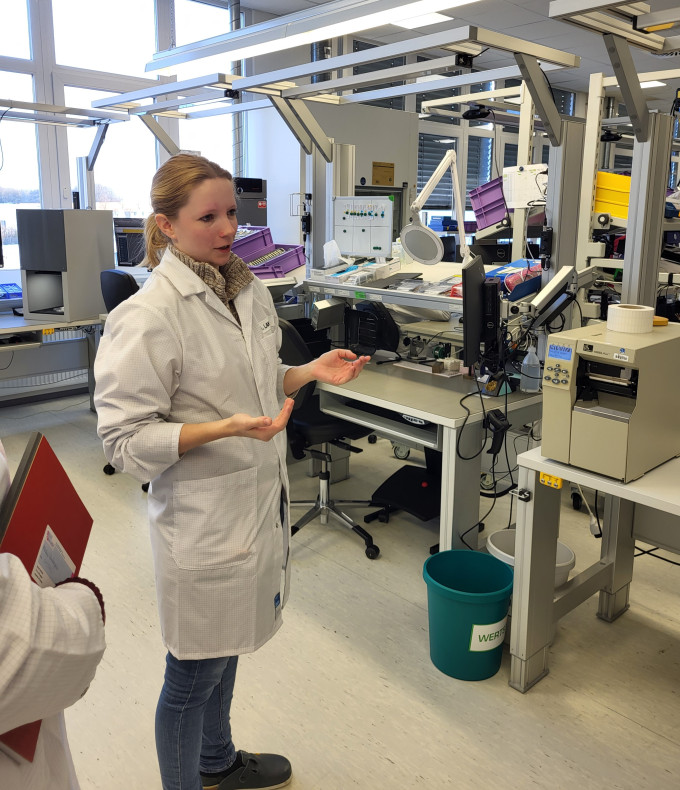

In the middle of last year, PI DPG launched the lean management project “Leica Line” under the leadership of Jasmin Lamm, Manager Lean Management and Factory Planning, as a pilot project. The goal was to streamline the production line and optimize the manufacturing flow by using lean methods and implementing the factory software “elution” from ELABO GmbH. Further project goals were the reduction of inventory levels at the production line as well as an ergonomic workplace design. Exemplary in this regard are the new modular worktables with electrical height adjustment - an example of the investments in our production, as Axel Widenhorn pointed out during the final presentation.

Immediately upon project completion, it could be seen directly that not only the processing time for the drive platform had been reduced by eight percent, but at the same time a higher output could be achieved. Further measures such as introducing the “5S” principles, the use of a digital assistance system, or the optimized flow of materials will help to further increase productivity and the yield of good pieces.

Informative Project with Promising Results

Dominik Hellmann, Manager Production Piezo Nexline - DPG, was very pleased with the results of the project. For example, the space required in the value stream for the line could be cut in half, which in turn means that valuable production space is now available otherwise. Several unnecessary work steps could be eliminated and environmental aspects like the avoidance of polystyrene waste were also taken into account. The high level of employee engagement during the project was also of great importance:

All five project phases were supported by the input of the team. I would like to take this opportunity to thank everyone involved. The team came up with so many ideas for improvement that it was not possible to implement them all. My thank also goes to Jasmin Lamm for the successful moderation of the project. During the whole project, we all learned a lot and built up methodological know-how.

For Jasmin Lamm, the project was also very informative:

For me, this was the first lean management project at PI. I would like to thank all my colleagues on the line as well as from the Production Technology and Industrial Engineering division for their splendid work during the whole project. I felt welcome immediately and was able to learn a lot about the technologies of PI and their specific application in the products.

elution Factory Software Strengthens Personal Responsibility

The elution factory software which was introduced in the course of the project offers two essential elements: On the one hand, all work steps for assembling the Leica drive platform are documented by means of photos or videos. They guide the employees purposefully through the assembly process and also considerably simplify the training of new employees on the line. On the other hand, the documentation provides clear specifications for quality inspection, compliance with which is confirmed electronically by the employees. This enables complete process control, which in the case of internal and external complaints allows for a rapid root cause analysis and forms the basis for the further development of the production line.

Contact persons:

- Dr. Axel Widenhorn, Director Operations - DPG, Managing Director PI miCos GmbH & Managing Director IBS Ingenieurbüro GmbH

- Jasmin Lamm, Manager Lean Management and Factory Planning