Three Questions for Matthias Stiegler, Head of Lean Management & Processes

The Support Function Lean Management & Processes started on July 1, 2021, as did the initial Value Streams and Support Functions of PI DPG. What can we expect from it?

Our group is split into two but still closely intertwined, in Lean Management and Processes.

Lean Management stands for the original Japanese management philosophy from Toyota, which developed after the end of World War II in the 1950s: Due to the limited resources after the war, the company was forced to act within the already existing production environment at a maximally efficient, economical, and resources-saving way in order to manufacture products. From this, the Toyota Production System developed, according to whose principles we want to work in the future as well: We are as lean as possible, which means we do not waste and are focused on the value chain and needs of our customers.

Processes stand for all activities and measures required for documenting and defining the PI DPG processes and activities, while checking conformity and completeness. This means that the processes are documented and continually kept up to date, which is where the great challenge lies.

Where are your interfaces?

Interfaces are involved with each process, which is documented and checked:

Within PI DPG, we work closely with the Value Streams and Support Functions. Especially when defining, implementing, checking, and further developing processes.

The interfaces to the global functions are in any areas to whose processes we are linked: e.g., Global Sales & Marketing, Global Research & Platforms, or Global SCM. An important interface lies in the global function Quality and Integrated Management Systems (Werner Bitterwolf), so that the processes are depicted seamlessly and compliant to the IMS and the certified standards.

Which topics or projects do you push?

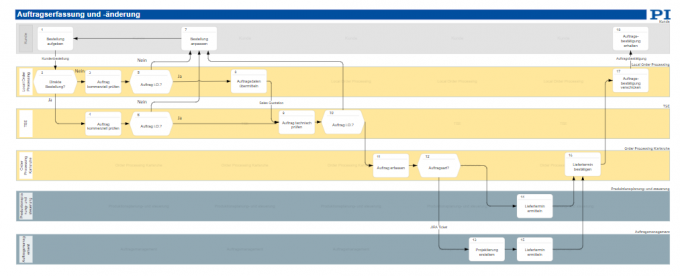

In the past few months and with the support of our consultant, Stephan Bakwitz, we started with the introduction of Shopfloor Management. Furthermore, we are working on the implementation of the planning software Felios. Both are methods and tools prescribed to Lean Management, with the goal for PI to be set up as efficiently as possible in the future, i.e., "without wastage". In addition, we use the viflow software to document processes in order to depict our processes in a transparent way [screenshot shows order entry and modification].